Best Uses for Arbor Press by Force Capacity

Back to Top

Back to Top

Which press should you use for your process?

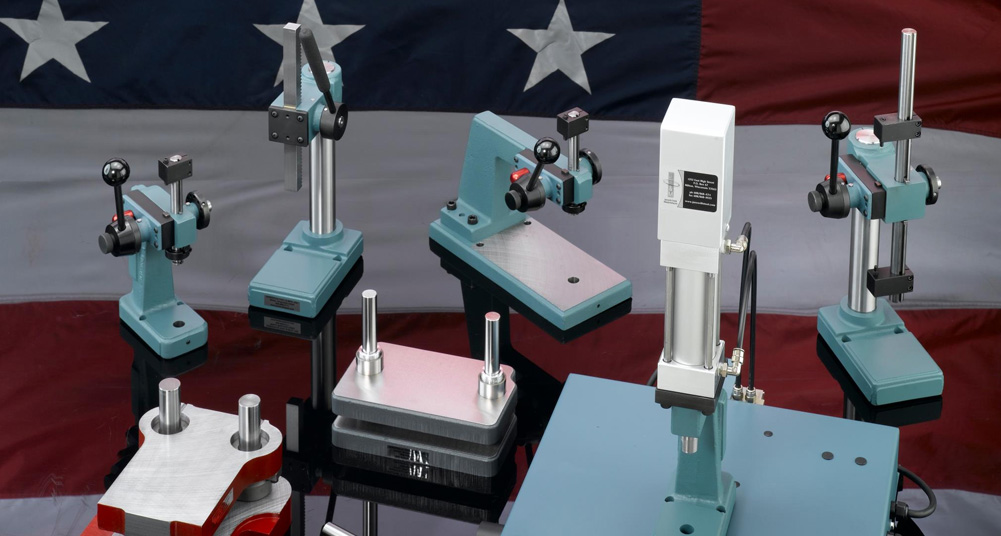

The right arbor press can simplify repetitive assembly and fabrication processes that require consistent pressure for stamping, assembling, or forming workpieces. There are a lot of factors to consider when you're thinking about adding a Janesville Tool arbor press to your production facility. Some of those factors include:

Pneumatic or manual?

For high repetition manufacturing processes, a pneumatic press may be best. A pneumatic press will apply the same force for hundreds or thousands of cycles per day, minimizing physical strain on your manufacturing team members. A manual arbor press requires less maintenance to run, it also does not require a pressurized air supply. For some delicate operations like press-fitting parts, a manual press offers the advantage of being able to feel when you've applied the correct amount of pressure.

Force requirements

Most applications require specific force. Too much and you risk breaking the workpiece, too little will result in a flawed finished product. Pneumatic and manual presses both range in force from 1/8th ton to 4 ton. Applications like assembly may require a lower force output, while cutting, stamping and riveting may require more.

Proper stroke length

Getting the proper amount of ram travel can be essential to efficiency. If the stroke length is too long it can cause unnecessary slack in your assembly process that wastes time and energy, as well as tax the duty cycle of your air compressor for pneumatic presses. If your stroke length is too short it can cause an improper seat for assembly parts.

Made in the USA

Made in the USA